3D Printing vs. Traditional Manufacturing: Which is Right for Your Business?

Understanding the Basics of 3D Printing and Traditional Manufacturing

In today's rapidly evolving technological landscape, businesses are constantly seeking innovative ways to produce high-quality products. Two prominent methods stand at the forefront: 3D printing and traditional manufacturing. While both have their distinct advantages and challenges, choosing the right one for your business depends on various factors including cost, efficiency, and product complexity.

The Advantages of 3D Printing

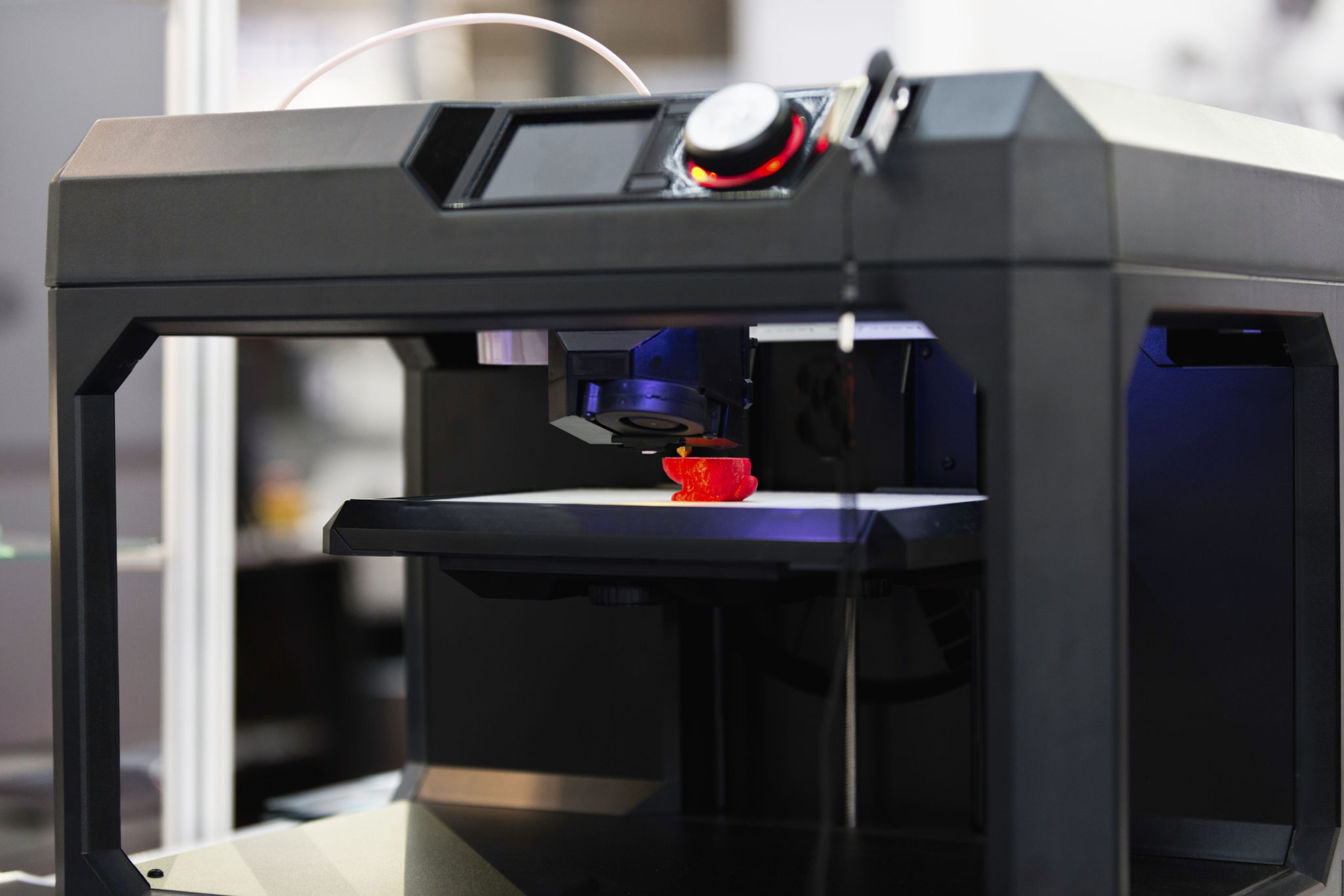

3D printing, also known as additive manufacturing, offers several unique benefits that traditional methods may not provide. One of the primary advantages is the ability to produce complex geometries that would be impossible or costly with traditional techniques. This flexibility allows for rapid prototyping, enabling businesses to iterate quickly on design concepts.

Another significant advantage of 3D printing is its cost-effectiveness for short production runs. Since it eliminates the need for expensive molds and tooling, businesses can save on initial setup costs. Additionally, 3D printing reduces material waste, as objects are built layer by layer, using only the necessary material.

Benefits of Traditional Manufacturing

On the other hand, traditional manufacturing methods like injection molding, CNC machining, and casting offer their own set of benefits. These techniques are well-suited for mass production, providing economies of scale that can significantly lower per-unit costs. For businesses looking to produce large quantities of standardized products, traditional manufacturing is often the more economical choice.

Furthermore, traditional methods are renowned for their reliability and precision. They are capable of producing products with high mechanical strength and durability, which are critical in industries such as automotive and aerospace. For applications where product longevity and structural integrity are paramount, traditional manufacturing remains a strong contender.

Factors to Consider When Choosing Between 3D Printing and Traditional Manufacturing

When deciding which method to adopt, businesses should consider several factors.

- Volume: For low-volume or custom products, 3D printing might be more suitable, while traditional manufacturing is better for high-volume production.

- Complexity: If your product design involves intricate details or internal structures, 3D printing can achieve these with ease.

- Material Requirements: Traditional manufacturing often supports a wider range of materials that might be necessary for specific industry standards.

The Role of Technology and Innovation

The choice between 3D printing and traditional manufacturing is also influenced by technological advancements. As 3D printing technology continues to evolve, its applications are becoming more diverse and economically viable. Innovations in materials and printing speed are helping bridge the gap between these two manufacturing methods.

Ultimately, businesses should remain open to adopting a hybrid approach that leverages the strengths of both methods. By doing so, they can optimize production processes, reduce costs, and remain competitive in an ever-changing marketplace.

Conclusion: Making the Right Decision for Your Business

In conclusion, there is no one-size-fits-all answer when it comes to choosing between 3D printing and traditional manufacturing. Each business must assess its unique needs, considering factors such as cost-efficiency, production timelines, and product specifications. By understanding the strengths and limitations of each method, businesses can make informed decisions that align with their strategic goals.

Whether you opt for the cutting-edge capabilities of 3D printing or the tried-and-true reliability of traditional manufacturing, the key is to stay informed and adaptable in a world where technology continues to redefine what's possible in production.