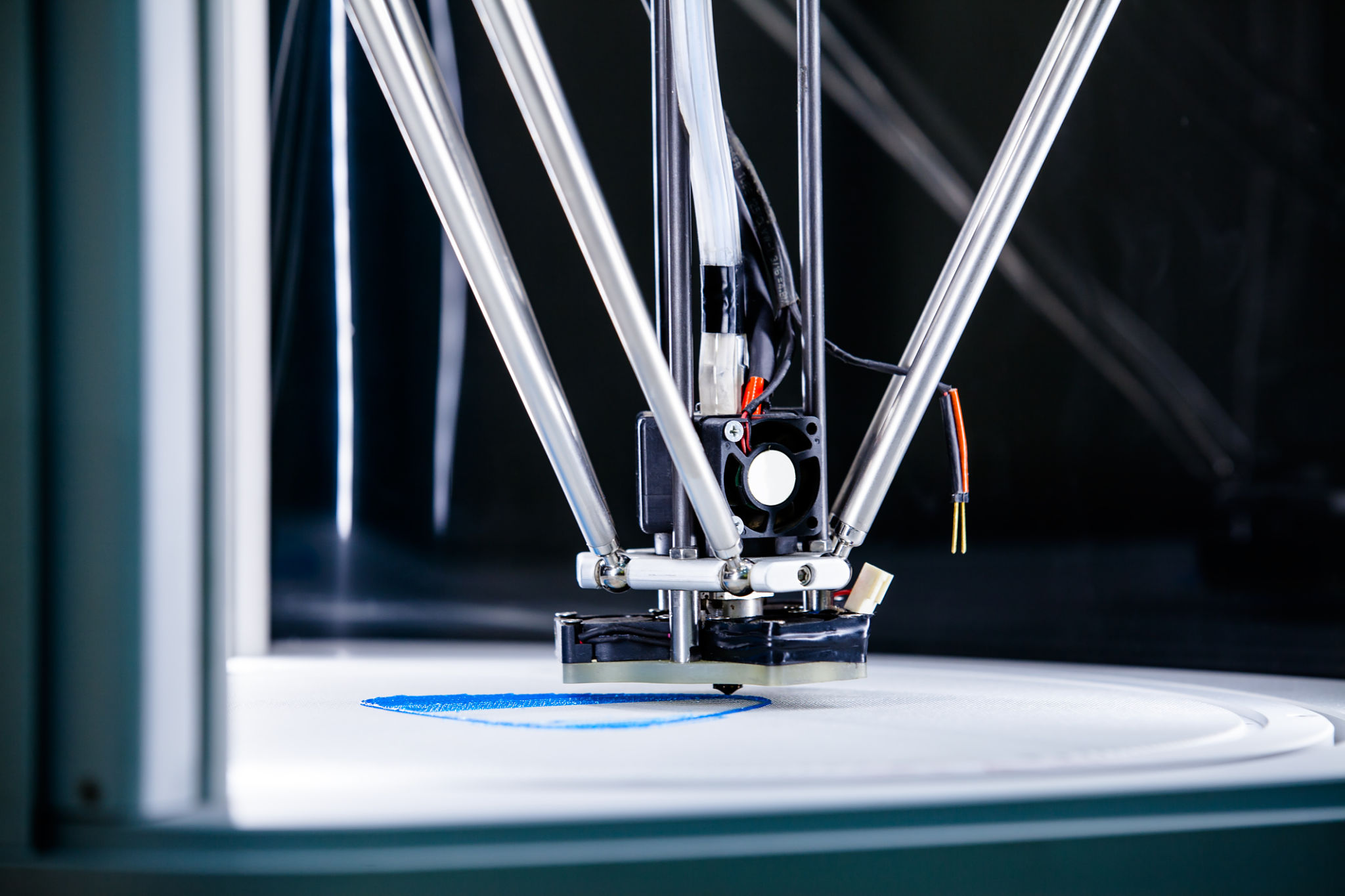

Top 5 Trends in 3D Printing and How They Affect Your Business

Embracing the Future: 3D Printing Trends

In recent years, 3D printing has evolved from a niche technology into a powerful tool that is transforming industries. From manufacturing to healthcare, businesses are leveraging the advantages of 3D printing to streamline operations, reduce costs, and foster innovation. Here, we explore the top five trends in 3D printing and how they can impact your business.

1. Advanced Materials

The development of advanced materials is revolutionizing 3D printing. Gone are the days when only plastics were used. Today, businesses can utilize metals, ceramics, and even biocompatible materials, opening up a myriad of possibilities. This trend allows companies to produce durable and high-performance components that were previously impossible to manufacture.

For businesses, this means an opportunity to create more robust products with complex geometries that are tailored to specific needs. Whether it's aerospace components or medical implants, the use of advanced materials in 3D printing can significantly enhance product quality and functionality.

2. Customization and Personalization

One of the most exciting aspects of 3D printing is its ability to offer customization and personalization at scale. This trend is particularly beneficial for industries such as fashion, healthcare, and consumer goods, where individual preferences and specific requirements are essential.

By leveraging 3D printing, businesses can offer personalized products without the need for costly molds or tools. This customization not only adds value but also improves customer satisfaction and loyalty. As a result, companies can differentiate themselves in increasingly competitive markets.

3. Sustainability Initiatives

With growing environmental concerns, sustainability has become a top priority for many businesses. 3D printing contributes to sustainability by reducing waste and optimizing resource use. Unlike traditional manufacturing methods that often result in material wastage, 3D printing uses only the exact amount of material needed, minimizing waste.

For businesses aiming to reduce their carbon footprint, adopting 3D printing can be a strategic move towards achieving sustainability goals. Additionally, the ability to produce parts locally reduces the need for transportation, further lowering emissions.

4. Decentralized Manufacturing

The rise of decentralized manufacturing is reshaping how businesses operate globally. With 3D printers becoming more accessible and affordable, companies are setting up localized production units closer to their customers. This trend reduces dependency on large-scale manufacturing facilities and complex supply chains.

For businesses, decentralized manufacturing means faster production times, reduced shipping costs, and increased flexibility in responding to market demands. By adopting this model, companies can remain agile and better serve their customers' needs.

5. Integration with AI and IoT

The integration of 3D printing with artificial intelligence (AI) and the Internet of Things (IoT) is unlocking new possibilities for innovation. AI algorithms can optimize print designs for efficiency and performance, while IoT-enabled printers allow for real-time monitoring and management.

This trend enables businesses to enhance their production processes with predictive maintenance and automated quality control. By integrating these technologies, companies can improve operational efficiency and reduce downtime, leading to increased productivity and cost savings.

In conclusion, staying informed about the latest trends in 3D printing is crucial for businesses looking to maintain a competitive edge. By embracing these advancements, companies can unlock new opportunities for innovation, improve sustainability, and deliver customized solutions that meet the ever-evolving needs of consumers.